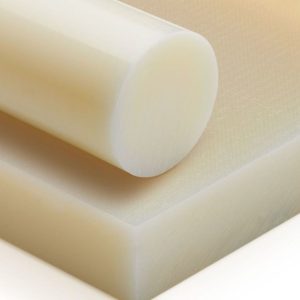

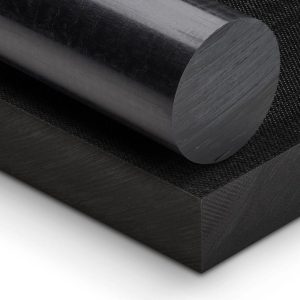

PA6G

Semi-crystalline polymer polyamide 6 (PA6) has good general properties and excellent quality and price. The use of high viscosity raw materials to produce polyamide 6 (PA6) keeps the molds at an excellent level. The mechanical strength as well as the slip properties on the surface of polyamide 6 (PA6) are not comparable to other materials with low viscosity. The special baking process of this product gives this product dimensional stability and excellent machining.

Description

Advantages

- It is resistant to abrasion in hard and severe applications.

- It is more resistant to pressure than polyamide 6 (PA6) and in fact has a much higher resistance to shock, impact and pressure.

- In all thicknesses and diameters, it has a higher quality than polyamide 6 (PA6).

- It is a lubricant and its low coefficient of friction means that it does not need lubrication in sliding tensile affairs.

- It has antistatic nature when absorbing moisture.

Disadvantages

- It has a higher moisture absorption ratio than polyamide 6 (PA6) and polyamide 66 (PA66).

Application

- Generally not used in contact with food products.

Possibility of having semi-finished parts with large dimensions. A very useful material in the mechanical industry for use in large gears, - pulleys, wheels, bearings and machine construction, as well as shaking when the gears are moving on the ground.

- Variety of electrical properties with varied absorption of moisture within the limits of use in the electrical field.

- Good resistance to alkalinization and mineral and solvent compounds.

Polyamide cast (PA6G) is produced and supplied in the form of SHEETS, RODS and TUBES in different dimensions and sizes.

Shipping & Delivery

Be the first to review “PA6G” Cancel reply

Reviews

There are no reviews yet.