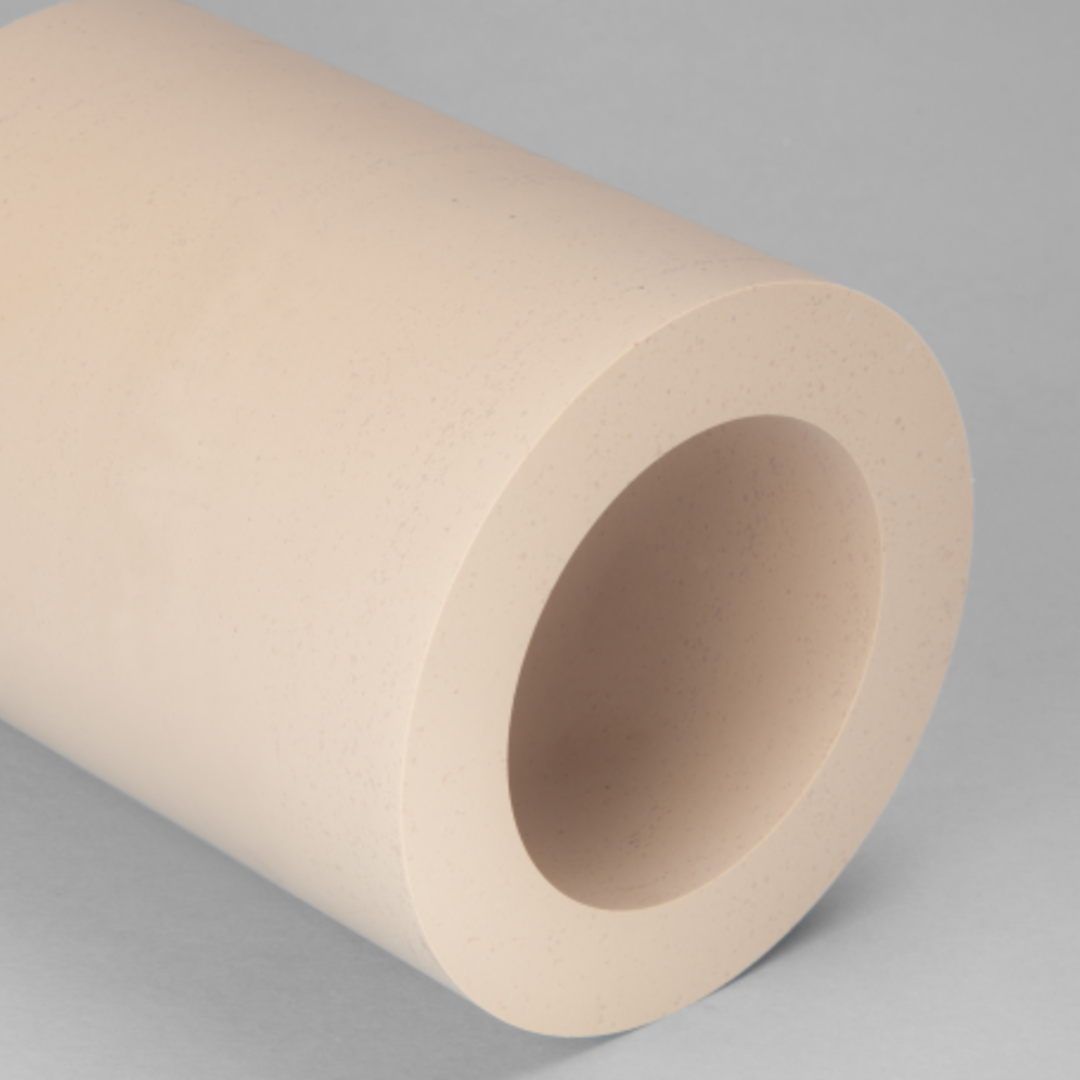

PTFE+25%Glass

Teflon PTFE is a mixture of 25% glass (PTFE glass or PTFE + 25% Glass) reinforced for high creep resistance in all temperature ranges. Suitable for all types of valve seals and washers in pressure tolerant conditions.

Teflon glass (PTFE + Glass) has a modified coating resistance and due to the insulation of glass fibers has little effect on its electrical properties. Teflon glass 25% (PTFE glass or PTFE + 25% Glass) has excellent water resistance.

The presence of glass fibers increases the anti-wear properties and also provides greater strength against deformation when applying pressure. These changes while the electrical and chemical properties of Teflon (PTFE) remain unchanged. This product also has a higher coefficient of friction. Of course, glass has poor resistance to alkalis.

However, Teflon mixed with 25% glass is not suitable for applications that require resistance to bases and hydrofluoric acid and should be avoided in these applications.

PTFE+40%Bronze

Teflon mixed with 40% bronze (PTFE + 40% Bronze) is a creep-modified alloy compared to other Teflon alloys. This type of Teflon PTFE has reinforced thermal conductivity with a very high pressure bearing capacity. Therefore, it is very suitable for use in hydraulic systems. Teflon bronze is a conductor of heat and electricity and despite its good dimensional strength, it has high compressive strength and resistance to creep due to its hardness.

Teflon bronze products (PTFE + Bronze) have better abrasion resistance and higher thermal conductivity than Teflon fiberglass products. This combination has better machining capabilities.

But exposed to acids and bases, it has less chemical resistance. The combination of Teflon bronze is very useful in operations under high mechanical pressure and high speed wear. Because it provides the power and conductivity needed to control excessive and unwanted heat.

The Teflon bronze compound (PTFE + Bronze) is also known as Tetron B. Bronze is made of an alloy of copper and tin, which has better abrasion resistance than all other Teflon compounds. The Teflon bronze composition is bold brown and a stainless alloy is added for a better appearance.

PTFE+CarbonCeramic

The PTFE mix with carbon, when combined with ceramic, improves the coefficient of thermal expansion and wear properties, which is why it is used in the ring of non-lubricated pistons.

It is mainly used in cases that require high resistance to wear under high pressure. These include piston rings for dry compressors, bearings and mechanical retainers.

PTFE+35%Carbon

In Teflon PTFE 35% carbon (PTFE 35% carbon or PTFE + 35% Carbon), 35% carbon and a small percentage of graphite are added to virgin Teflon (PTFE).

Carbon significantly improves the erosion and metamorphic strength of the material and its chemical resistance remains relatively unchanged. However, the electrical properties of the material also increase significantly.

Also, with increasing carbon, the amount of tensile strength and elongation increases.

PTFE+25%Carbon

Teflon PTFE mixed with 25% carbon (PTFE carbon or PTFE + 25% Carbon) is one of the fluorinated Teflon with 23% carbon and 2% graphite added to Virgin Teflon (PTFE) and has Relatively better features compared to Virgin Teflon (PTFE) and naturally available in black on the market.

Carbon significantly improves the erosion and metamorphic strength of the material and its chemical resistance remains relatively unchanged. However, the electrical properties of the material also increase significantly.

Teflon carbon (PTFE + Carbon) is primarily used in cases where more thermal and electrical conductivity is required than Virgin Teflon PTFE.

It is also modified in durability and compressive strength to Virgin Teflon (PTFE), which makes it suitable for pressurized applications. Teflon carbon (PTFE + Carbon) has good resistance to creep, pressure tolerance, surface coating and abrasion in sliding or scratching applications in dry to lubricated conditions.

Teflon carbon (PTFE + Carbon) is the best type of reinforced Teflon for aquatic environments. It is also very suitable for dynamic applications at high speeds, because thermal conductivity reduces the accumulation of heat on the surface involved and therefore has a better lifespan than other Teflon in these conditions.

PTFE Compound

The development of technologies has helped to improve the properties of Virgin Teflon (PTFE) for various applications. Adding an appropriate amount of organic and inorganic fillers can improve some of the mechanical, chemical, thermal and electrical properties.

Up to 60% fillers can be added to quality Teflon (PTFE). The most common fillers are glass fibers, carbon, bronze, graphite and molybdenum disulfide.

Teflon (PTFE) does not easily enter the compound due to the neutrality of its chains. In fact, each filler must withstand temperatures above 400 ° C for several hours. This removes a lot of material alone.

Virgin PTFE

The basic properties of Teflon (polytetrafluoroethylene, PTFE) are due to the chemical structure of the polymer, which consists of a double bond of carbon and fluorine.

The size of the fluorine atom allows a uniform, continuous sheath to form around the carbon-carbon bonds to protect them from external attack. As a result, it causes the molecule to have chemical resistance and stability.

Teflon PTFE, on the other hand, retains its properties at very low temperatures. Therefore, it has many applications in important industries such as aerospace and industries that need to work at low temperatures, such as sealing liquid nitrogen tanks at -196 degrees and liquid hydrogen -253.